-

dedicace

Forum : Roger92 vous répond

Dernier message : listenandhear

07/02/2022, 11:41

» Réponses : 0

» Affichages : 619 -

Classics live II

Forum : Discographie

Dernier message : Syl76

27/05/2020, 13:18

» Réponses : 24

» Affichages : 10 722 -

Olympia 2019

Forum : Concerts (Souvenirs et à venir)

Dernier message : Syl76

16/02/2020, 10:54

» Réponses : 13

» Affichages : 2 678 -

Blainville Crevon 25 Juin...

Forum : Concerts (Souvenirs et à venir)

Dernier message : Syl76

08/10/2019, 12:34

» Réponses : 17

» Affichages : 7 177 -

ARÊNES DE NÎMES 11 JUILL...

Forum : Concerts (Souvenirs et à venir)

Dernier message : rhmila

18/09/2019, 16:30

» Réponses : 3

» Affichages : 784 -

Roger Hdogson et M à Nime...

Forum : Vidéos officielles, Articles de presse, Interviews, Emissions de radio...

Dernier message : rhmila

18/09/2019, 15:24

» Réponses : 1

» Affichages : 810 -

Colmar 2/08/2019

Forum : Concerts (Souvenirs et à venir)

Dernier message : camille73

10/08/2019, 21:49

» Réponses : 2

» Affichages : 686 -

Olympia 22 06 2014

Forum : Concerts (Souvenirs et à venir)

Dernier message : Syl76

03/08/2019, 12:45

» Réponses : 36

» Affichages : 13 104 -

CONCERT DU 01 JUIN

Forum : Concerts (Souvenirs et à venir)

Dernier message : cbell35

31/07/2019, 10:16

» Réponses : 7

» Affichages : 1 301 -

Touchy Coma au Bus Pallad...

Forum : Divers

Dernier message : rhmila

15/07/2019, 22:00

» Réponses : 1

» Affichages : 1 227

- Messages du forum :19 336

- Sujets du forum :1 227

- Membres :511

- Dernier membre :ujejwhgwygeu093

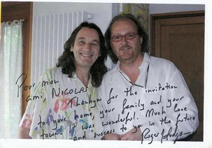

Bonjour,

j ai trouvé cette pochette de disque signée dans un lot,,,

j ai vraiment un doute apres qques recherches sur internet,,,

qu en pensez vous,,, svp

merci 1000 fois par avance

Cyril

14/08/2019, 14:39

Forum : Vidéos officielles, Articles de presse, Interviews, Emissions de radio...

- Réponses (1)

Bonjour à tous, des années que je ne m'étais pas connecté sur le forum.

Je me suis tout de même rappelé du mot de passe

Ceci pour dire que j'ai vu ces deux vidéos de Roger Hodgson et M à Nimes, c'est pas mal <!-- m --><a class="postlink" href="https://www.youtube.com/watch?v=tJ-4xjKkjWQ">https://www.youtube.com/watch?v=tJ-4xjKkjWQ</a><!-- m --> et <!-- m --><a class="postlink" href="https://www.youtube.com/watch?v=i2kz8AXyjpo">https://www.youtube.com/watch?v=i2kz8AXyjpo</a><!-- m -->

C'est de l'officiel Mathieu Chedid apparemment

enjoy

Superbe concert auquel j'ai assisté ce 2/08/2019.

Le public était survolté!Il a réservé un très bon accueil à Roger.

Bonjour,

Je ne suis pas prêt, aussi, d'oublier le concert de Nîmes..

EXCEPTIONNEL AVEC M venu accompagner Roger sur Don't Leave Me Now....et sur GIVE A LITTLE BIT à la fin...

QUEL SOLO sur Don't Leave me now....UNE VRAIE BELLE SURPRISE....

hello,

J'ai pris ma place pour Cognac

Voici le programme de la journée (mail de l'organisation):

Le samedi 6 juillet 2019, les concerts gratuits débuteront dans le Jardin Public à partir de 10H00 et jusqu'à 17H15.

A partir de 18H15, ouverture des portes pour la soirée payante.

A ce jour, sous réserves de modifications, les horaires des concerts sont les suivants :

19H00 Gino Mateo

20H15 Roger Hodgson (scène principale)

21H45 Fantastic Negrito

22H45 Garbage (scène principale)

00H15 Kaz Hawkins

Les concerts se déroulent en plein air dans l'enceinte du Jardin Public de la ville de Cognac, il n'y a pas de gradin, vous avez la possibilité de vous asseoir sur le théâtre de verdure qui est composé de marche à même le sol

Avis aux amateurs, à bientôt peut-être…..

Thierry

Bonjour à tous et à toutes,

Content d'avoir revu Roger depuis 2 ans ...déjà...

Beau concert malgré la Fatigue de Roger qui était un peu juste au niveau voix (cela reste mon avis...) mais qui reste d'une gentillesse et toujours plein d'humour...

De très beaux morceaux (avec les deux nouveaux musiciens=très bons) avec de très beaux arrangements notamment don't leave me now.

J'ai adoré Child of Vision et If everyone was listening...MAGNIFIQUES..

Très content d'avoir revu Mila, Flo, Ccat, camille, sylvie, Thierry (Wurly) et les autres (désolé je ne me rappelle plus de vos prénoms...c'est l'âge), cela faisait longtemps.

Très belle ambiance et très bien placé au premier rang en face Roger (Merci Nicolas)...

On l'a revu après le concert dans la rue, à proximité de son Hotel. Il était très ouvert et d'une disponibilité rare...

CHAPEAU ROGER car il avait une tête vraiment fatiguée.

Je vais essayer de refaire une date cet été = Nimes sans doute.

Amitiés à tous et à toutes.

Bonjour

je vends deux places pour le concert du 1er juin, bien placées

merci de me contacter

à bientôt

Coucou à tous,

Je me permets de poster ce sujet, car depuis plusieurs mois, j'avais prévu d'aller voir Roger au Royal Alberall le vendredi 24 mai 2019, et d'y passer le week-end avec mon mari.

Malheureusement, les derniers évènements font que je ne pourrais m'y rendre.

C'est pourquoi, pour ceux qui seraient intéressés, je mets en vente une seule place de concert (mon mari n'ayant pas souhaité y aller) à 60 €, + l'hôtel 3 étoiles non loin de la salle à 180 € pour 2 nuits 2 personnes. Je propose un pacage à 210 € si sa intéresse quelqu'un.

Pour ceux qui seraient intéressés, merci de me contacter par Mp.

Enormes bisous, Camille73.

Question quelque peu récurrente, je sais, il y a les concerts qui prennent du temps et de l'énergie, qui ravis les fans. Mais pourquoi ce silence discographique qui déçoit ? Si je prends en comparaison un autre créateur (Paul McCartney) qui s'avère plus âgé, qui lui aussi n'arrete pas de tourner, depuis 2000 sauf erreur a sorti 6 albums studio. Désolé, mais moi cela me turlupine d'en connaitre la raison !!! :ange:

11/04/2019, 14:11

Forum : Vidéos officielles, Articles de presse, Interviews, Emissions de radio...

- Réponses (2)

Durant la dernière fete du cinéma, cette pub était passée, la salle pleine à craquer, mais pas insensible à repris en rythme tout le long du chemin de retour de la bande son de-qui-vous-savez !!!!! :]

<!-- m --><a class="postlink" href="https://www.youtube.com/watch?v=dg_IuSrcPm4">https://www.youtube.com/watch?v=dg_IuSrcPm4</a><!-- m -->